Project MGA

Growing up, my wife Sonia always wanted an MG, but her parents convinced her to save up and buy something "sensible". So this year, because we can, we decided to buy a lovely little 1962 MGA. When MGAs launched, they were quick, sporty, fun, and cheap. The spiritual precursor to the Miata, there are no door handles, basic interior, and no bells or whistles. I also think it has the nicest lines and curves of any classic car.

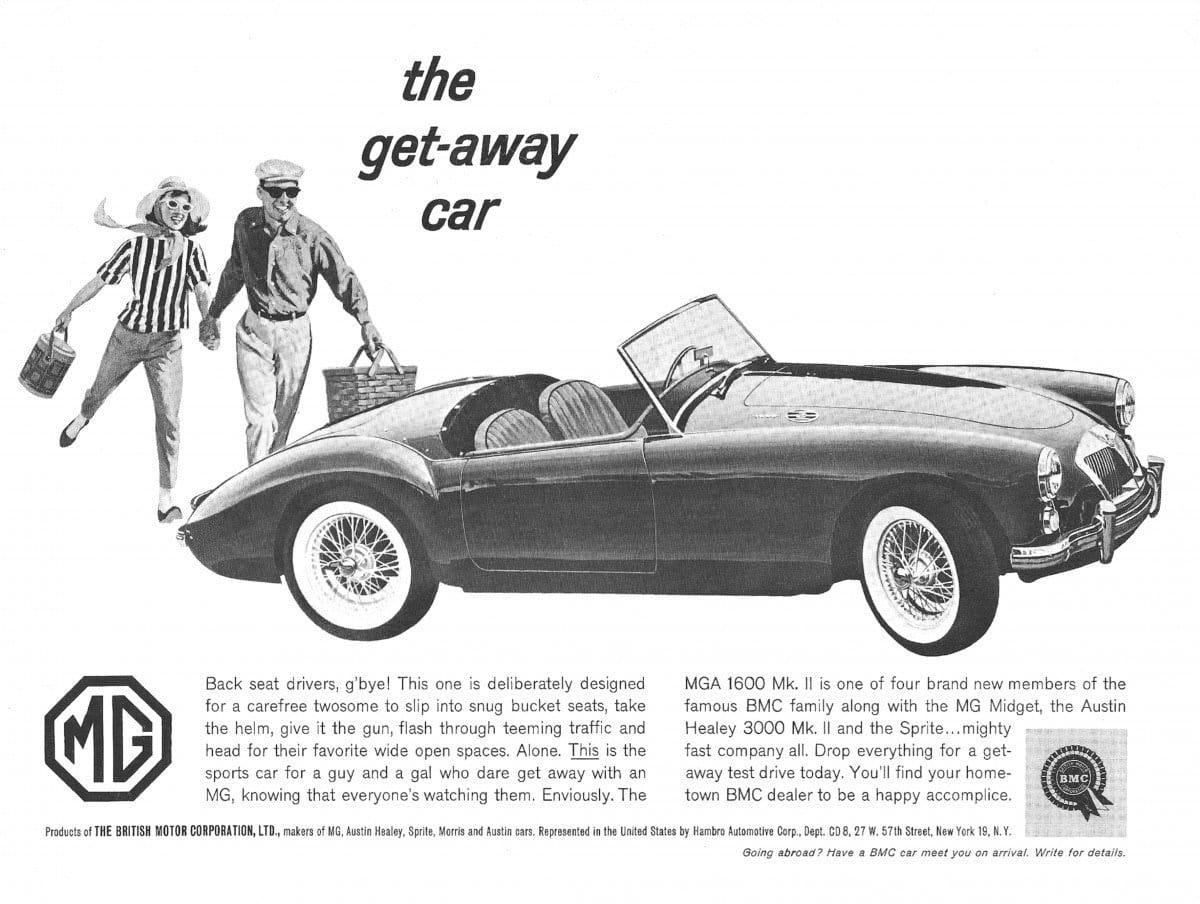

My favorite ad from the era is this one, that pitched the car as the romantic get-away car. There are only two seats, and very little boot space, just enough for a romantic weekend away for a couple.

Here is what (I hope!) it will look like when it is finished:

Doing it ourselves

We are fully restoring it ourselves – removing all the body panels, stripping them back to bare metal, painting it, replacing all the wiring, adding power steering, and making a number of improvements and restoration details along the way. It will essentially be a new car when we've finished.

About the only thing we aren't doing ourselves is the upholstery, which we are getting made by a small family business in the UK and sent over, but we will install it ourselves. Otherwise, all body work, painting and mechanical work is being done by us and us alone.

We started the restoration in July 2024, and so far we are 3 months in. We've disassembled most of the car (I'm told this is the easy bit) and stripped, repaired, welded, and primed the 4 front and rear fenders.

Here is a timelapse of the journey so far:

About the car

Our car was first built in the UK in 1961 at the MG Abingdon factory. At the time, Australia had tarrifs on the import of assembled cars, to try to protect and grow the local car industry. So after being built, this car and hundreds of others was dissassembled down into pieces (CKD or Completely Knocked Down), shipped to Australia, and reassembled in Sydney and sold to the first owner in 1962. It's a 1600 Mk II, the last line of MGA's produced.

Here is the car when we bought it. We bought it from a lovely gentleman in Sydney and drove it back to Brisbane. She ran fine, and from the photo she looks good, but photos are deceiving. The paint was cracked and bumped and generally calling out to be re-done. The paint isn't original anyway, and there are many layers of paint underneath it. We'll be changing the outside to Mineral Blue, a rich navy blue colour, and the inside to a tan leather.

We didn't originally intend to restore it ourselves. Honestly, we knew nothing about restoring cars. We shopped around for some quotes from local restorers, but each one was worse than the last.

"$50K and 18 months" - this is the general ballpark of the quotes we got. Ouch!

"How hard can it be?"

At this point, I started going down the web/YouTube rabbit hole.

"How hard can it be? The paint is probably $2000, and if we do it to our schedule I reckon we'll get it done in 6 months!" said I. Oh, was I naive!

But the "how hard can it be" mindset is my superpower. "How hard can it be?" enables you to take a leap of faith and jump into something without over-thinking it. At both the macro and the micro level, it allows you to climb the stairs one step at a time. "TIG welding... how hard can it be?". Watch a few YouTube videos, bet on yourself that you can figure it out, get the equipment, and have a go. Accept you'll fail, and keep going.

This mindset is how I started the adventure of building Octopus and also renovating our house, where I did everything from framing to plumbing to electrical. I'd never have done any of these things if I knew how hard they were!

In fact, here's a whole list of things I've learned over the last 20 years that started with "how hard can it be" and a few YouTube videos and Google searches:

- Learning C/C++, Python, then C#, plus a bunch of other programming topics along the way (I didn't go to university)

- Building Octopus Deploy, and all of the big and small things it took to get to $100M in revenue / 300 employees around the world

- Framing a garage, installing windows, roofing and cladding

- Building a fence with a sliding electric gate

- Replacing a toilet

- Driving a backhoe

- Cutting a hole in my roof and installing an air conditioner

- Installing a solar battery bank

- Wiring electrical outlets, lights and EV chargers

- Towing, launching, and driving a boat

- Drilling holes in the bottom of said boat to install trim tabs

- Building 3 different IKEA kitchens

- Building a deck

- Installing a security alarm system

- Building beds and furniture for our kids

Until now, though, our cars were black boxes. I learned to drive in modern cars where if an alert pops up you "take it to the shop" and get it fixed. So this project has opened up a whole new world.

New challenges

This project is also forcing me to accept that good results take time and, instead of rushing to finish the car, to relax, trust the process, and enjoy the journey. For most other projects, about 50% of the way in, I regret taking it on and wish I'd paid someone else to do it. I don't think that's going to happen with this one. I'm deeply enjoying every minute of this project, even the tedious bits of grinding off decades of old paint.

A nice project car

I think we accidentally stumbled onto the perfect project car.

- As far as classic cars go, they are very cheap. A running Jaguar from this era would be $250K. A running MGA can be found for $40K.

- It's a small car, so there just isn't a lot of surface area to worry about. Two seats. Small boot. No roof. Easy access to everything.

- Very simple electronics - in fact only a few things on the dashboard are electronic at all. Most of it no more complex than a kid's bicycle.

- They are rare - only 100,000 were produced, and only 8,000 of those were Mk II which have some distinguishing features. So you see a couple at classic car shows, but they aren't everywhere.

- They can do modern motorway speeds, unlike some of the pre-war cars

- But they are common and cheap enough that a lot of spare parts are available at good prices. A local company in Australia even makes most of the body panels to original dimensions.

- It's extremely well documented. Barney Gaylord maintains MGA Guru with over 4,000 pages on every aspect of the car. The MG Experience Forum has thousands of members sharing their adventures restoring the car.

To stay true to original, or modernise?

One of the big debates is how true we should stay to the original car, and how much we should make it our own.

The framework we came up with is this:

We want it to feel like a car of the era, but we also want no regrets, and we want to feel like it's reliable enough that we won't ever find ourselves stranded on the highway and never wanting to take it out again. We also want to do a good enough job that, if kept in a garage, it will last 20+ years.

With that in mind:

- The color we picked is Mineral Blue, which was a colour you could order MGA Coupes in, but not Roadsters. Still, it's of the era, so definitely doesn't look out of place, compared to e.g., if we painted it in a metalic paint.

- The inside will be a tan leather, which we think looks great, and was an option at the time though not usually with Mineral Blue.

- We are sticking with most of the original other parts of the car, but taking extra care on the wiring, and will probably use modern heatshrink connectors to avoid electrical issues. British cars aren't known for their reliable electronics, but I think this is mostly care and maintenance.

When our children are married, I'd love this to be the car they drive away from their weddings in.